Innovative Powder Conveying Systems for 2025 Global Trade Strategies and Essential Checklist

As we look towards 2025, the global trade landscape is set to evolve dramatically, necessitating innovative approaches across various sectors. Among these, the Powder Conveying System will play a crucial role in optimizing manufacturing processes, as highlighted in recent industry reports projecting a compound annual growth rate (CAGR) of 5.2% in powder handling technologies by 2026. This growth is driven by the rising demand for efficient and reliable transportation of bulk materials in industries such as pharmaceuticals, food processing, and chemicals.

Companies that strategically integrate advanced powder conveying solutions will not only enhance their operational efficiencies but also improve product quality and safety standards. To remain competitive, it is essential to explore the top strategies associated with Powder Conveying Systems that align with the evolving needs of global trade. This blog will outline essential considerations and best practices to capitalize on these innovations, ensuring preparedness for the opportunities and challenges of the near future.

Key Takeaways:

- Understand the importance of Powder Conveying Systems.

- Stay updated on market trends and statistics.

- Implement best practices for operational efficiency.

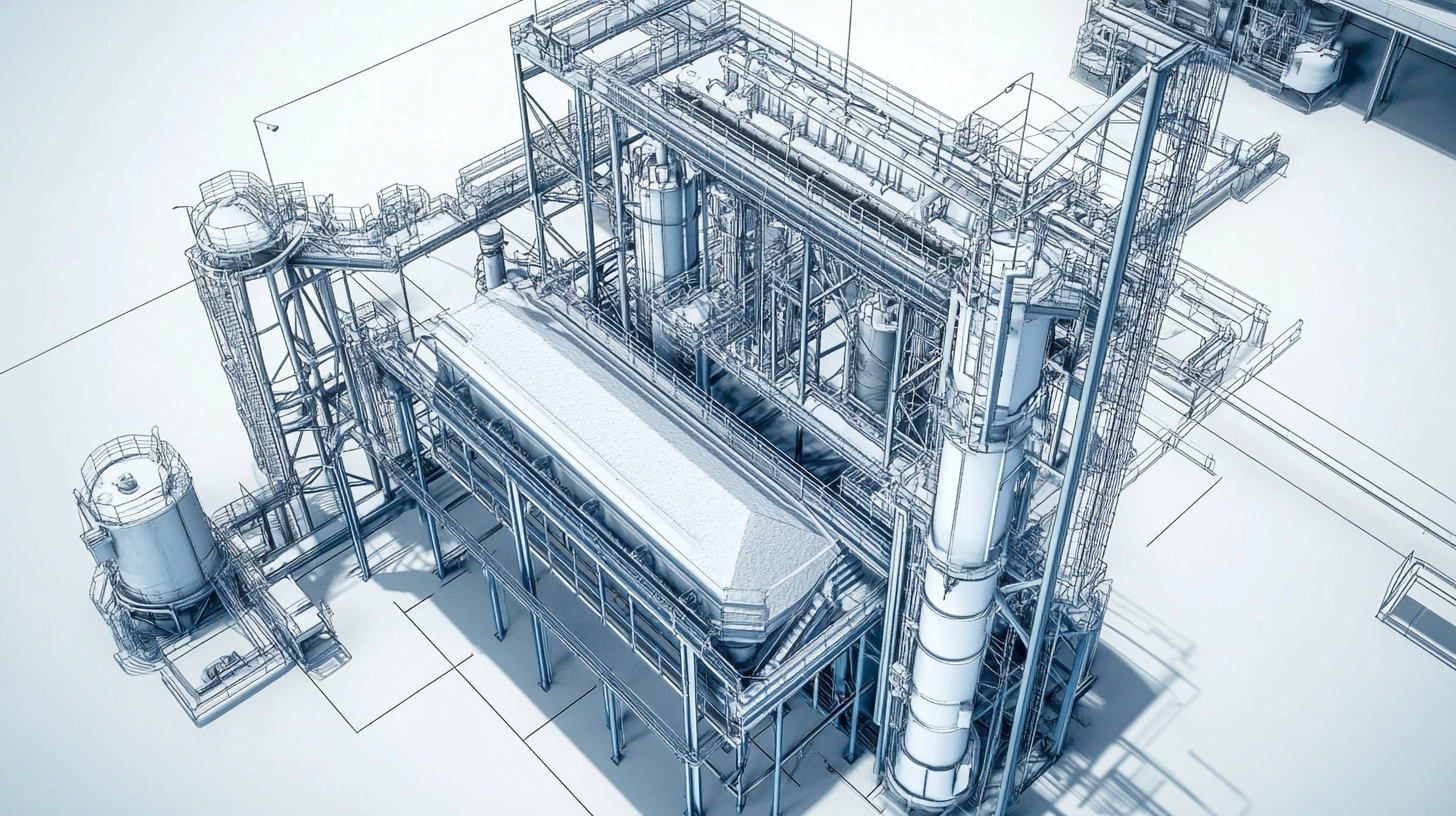

Innovative Approaches to Powder Conveying Systems for Future Trade

The landscape of global trade is shifting rapidly, and innovative approaches to powder conveying systems are essential to keep pace with these changes. According to a recent report by Freedonia Group, the global market for bulk material handling equipment is expected to reach $75 billion by 2025, driven largely by advancements in automation and efficiency. These innovative powder conveying systems not only enhance the speed and reliability of material transport but also reduce waste and lower operational costs, making them vital components for industries such as pharmaceuticals, food processing, and chemicals.

Moreover, the implementation of smart technologies, including IoT and AI, is revolutionizing powder conveying operations. A study by MarketsandMarkets indicates that the smart conveying systems market is projected to grow from $1.2 billion in 2020 to $3.8 billion by 2025, highlighting the increasing demand for data-driven solutions that optimize performance and predictive maintenance. By focusing on these innovative approaches, companies can streamline their supply chains, enhance productivity, and ultimately gain a competitive edge in the evolving global trade environment.

Adapting Powder Conveying Technologies for Global Supply Chains

In the evolving landscape of global supply chains, the adaptation of powder conveying technologies is becoming increasingly critical. According to a report by MarketsandMarkets, the powder handling market is projected to reach USD 38.59 billion by 2025, driven by the need for efficiency and precision in material handling processes. As manufacturers aim to streamline operations and reduce costs, innovative powder conveying systems—capable of minimizing waste and enhancing productivity—are pivotal. These systems not only ensure the safe transfer of materials but also comply with stringent regulations on sanitation and safety, which are becoming more prominent in international trade.

Advancements in technologies such as pneumatic conveying and modular systems have begun to reshape the way industries handle bulk powders. A study from Grand View Research highlights that the pneumatic conveying segment alone is anticipated to grow at a CAGR of 6.8% from 2023 to 2030, indicating a strong shift towards automation and efficiency. This shift aligns with the broader trend of digital transformation in supply chains, as manufacturers increasingly rely on data analytics and IoT to optimize processes. As businesses prepare for the challenges of 2025, implementing these innovative powder conveying systems will be essential for maintaining competitive advantage in a fast-paced global market.

Innovative Powder Conveying Systems for 2025 Global Trade Strategies and Essential Checklist

| Dimension | Value |

|---|---|

| Market Growth Rate | 6.5% CAGR (2023-2025) |

| Key Challenges | Supply Chain Disruptions |

| Investment Opportunities | Automation and IoT Integration |

| Preferred Technologies | Pneumatic and Mechanical Systems |

| Environmental Impact | Low Carbon Emissions Technologies |

| Emerging Markets | Asia-Pacific and Latin America |

| Regulatory Trends | Stricter Quality Standards |

| Supply Chain Strategies | Diversification and Resilience |

Key Strategies for Enhancing Powder Conveying Efficiency and Sustainability

As industries navigate the complexities of global trade in 2025, enhancing the efficiency and sustainability of powder conveying systems becomes paramount. Recent studies indicate that optimizing these systems can lead to cost reductions of up to 20% and a significant decrease in energy consumption, essential in today’s eco-conscious market. Innovations in pneumatic conveying technology, for instance, have demonstrated the ability to streamline operations while minimizing the carbon footprint associated with traditional methods.

Tip: Implementing smart sensors and IoT solutions can dramatically improve the monitoring of conveying systems. These technologies enable real-time data analysis, leading to predictive maintenance and reduced downtime, ultimately enhancing operational efficiency.

Furthermore, investing in sustainable materials and practices can complement these technological advancements. For example, using biodegradable polymers for conveying components not only reduces environmental impact but also aligns with global sustainability goals. According to the Powder and Bulk Engineering Survey, 75% of companies in the powder processing sector are prioritizing sustainability initiatives in their strategic planning.

Tip: Regular training for employees on best practices in powder handling can lead to improved process efficiency. Empowering staff with knowledge on equipment use and maintenance helps cultivate a culture of sustainability within the organization.

Checklist for Implementing Advanced Powder Conveying Solutions

As the global trade landscape evolves, businesses are increasingly focused on implementing advanced powder conveying solutions to streamline operations. A critical step for companies in 2025 will be to adopt a comprehensive checklist to ensure the successful integration of these innovative systems. Key considerations include evaluating materials, testing systems for specific applications, and understanding the unique demands of the products being conveyed. The rise of specialized testing facilities allows processors to conduct trials, offering a crucial advantage in selecting the most effective conveying equipment before making significant investments.

Partnerships between manufacturers are also changing the game, enabling the development of integrated solutions tailored to meet specific industrial needs. For instance, advancements in automation and high-capacity systems are redefining standards for efficiency in sectors such as food processing and battery manufacturing. By focusing on meticulous material testing and collaborative innovation, companies can position themselves for agility and success in an increasingly competitive market. Adopting these strategies ensures not only optimal performance but also drives growth in a rapidly transforming industry.

The Role of Chinese Manufacturing in Global Powder Conveying Innovations

In the dynamic landscape of global trade, Chinese manufacturing has emerged as a pivotal player in the innovation of powder conveying systems. According to a recent report by MarketsandMarkets, the global powder conveying market is projected to reach USD 4.5 billion by 2025, with a significant contribution from Chinese manufacturers who are continuously advancing technology to meet international standards. Innovations such as pneumatic conveying systems and advanced vacuum technology are enhancing the efficiency and reliability of powder transport and processing.

Moreover, the expanding focus on Industry 4.0 presents numerous opportunities for China to lead in smart manufacturing solutions within this sector. A study from McKinsey highlights that up to 80% of manufacturing companies in China are prioritizing digital transformation to integrate automated systems and real-time data analytics into their operations. These advancements not only improve operational efficiency but also ensure that Chinese manufacturers can compete effectively in the global market, responding swiftly to evolving trade strategies and demands for sustainable practices.

Innovative Powder Conveying Systems: Global Insights 2025

This chart illustrates the projected growth in demand for innovative powder conveying systems across various industries globally, highlighting the significant role of Chinese manufacturing in meeting these needs.