2026 Best Injection Molding Machine With Robot Features?

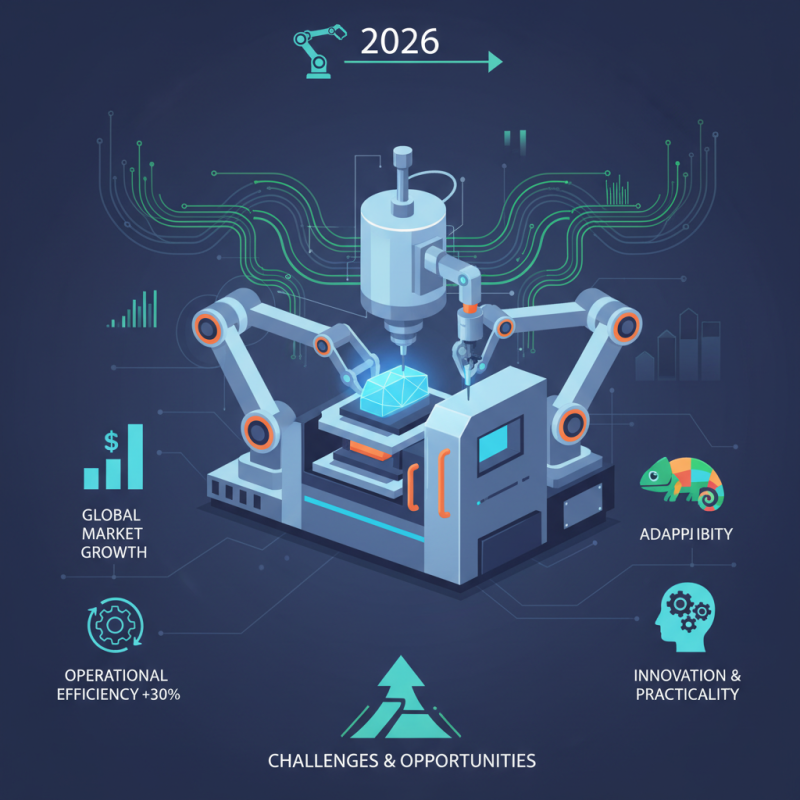

The injection molding industry is evolving rapidly, driven by technological advancements. The integration of robotics in manufacturing processes is a key trend. According to AIM Institute, the global market for injection molding machines is projected to reach $22 billion by 2027, with robots playing a significant role. This growth highlights the increasing demand for efficiency and precision.

Injection molding machines with robot features are not just a luxury; they are becoming essential. These machines enhance productivity and reduce labor costs. A study by MarketsandMarkets shows that automation can increase operational efficiency by up to 30%. However, integrating robots isn’t without challenges. Companies must navigate the learning curve of automation and potential initial costs.

In 2026, the best Injection Molding Machine With Robot features will likely prioritize adaptability. Manufacturers need machines that can handle various materials while maintaining high-quality output. Reflection on these integrations is necessary. Not all companies will adapt equally, and those that overlook potential downsides may struggle. Balancing innovation with practicality will be crucial for success.

Overview of Injection Molding Machines and Their Importance

Injection molding machines play a crucial role in manufacturing. They help produce a vast range of products, from automotive parts to household items. The efficiency of these machines affects production speed and cost. Understanding their importance is essential for any business in the manufacturing sector.

Here are a few tips: always analyze your production needs. Consider the volume and complexity of parts you are producing. Investing in machines with advanced technology can enhance precision.

Look for features like automation, which can streamline the process. A robot integrated into the system can handle repetitive tasks efficiently. This allows human workers to focus on more critical areas.

Maintenance is often overlooked. Regularly check the machine's components to avoid breakdowns. A small issue can lead to significant downtime. Being proactive can save costs in the long run. Finally, ensure that your team is trained. Well-trained operators can maximize the machine's capabilities and troubleshoot minor problems.

Key Features to Look for in a 2026 Injection Molding Machine

When exploring the features for the best injection molding machines in 2026, several key factors stand out. One essential feature is the advanced robotic integration. Machines equipped with robotic arms can enhance efficiency. They streamline the production process by automating tasks, such as loading and unloading materials. This reduces manual labor and minimizes human errors.

Another critical aspect is the machine's energy efficiency. The latest models focus on reducing power consumption. Look for machines with features that allow better energy management. This can lead to significant cost savings over time. Additionally, consider machines with adaptive control systems. These systems adjust parameters in real-time, ensuring optimal performance.

Tip: Always check the machine's maintenance requirements. A complex system may lead to prolonged downtime. Simple maintenance routines are vital for smooth operations.

Another important factor involves the machine’s precision. High precision ensures consistency in production. This is crucial for minimizing waste and ensuring high-quality output. Machines should also have a user-friendly interface. Operators need to navigate settings easily to maintain productivity. An intuitive design can save time and improve the overall workflow.

Tip: Don’t neglect the training aspect. Invest time in training operators thoroughly. Well-trained personnel are vital for maximizing the machine's potential.

Advantages of Integrating Robotics into Injection Molding Processes

Integrating robotics into injection molding processes offers significant advantages. It enhances precision and repeatability. Robots can perform tasks like loading materials and removing parts. This reduces human error. Automation creates consistent quality in every cycle.

The efficiency boost is notable. Production speed increases with fewer interruptions. Robots work tirelessly, maintaining high output rates. However, robotics integration requires careful planning. It's important to assess existing workflows. Sometimes, the transition can disrupt routine operations. Training staff to work with robotics is essential.

Cost savings emerge over time. Reducing labor costs while increasing throughput is appealing. Yet, returns on investment may take patience. Maintenance and downtime must be factors in the planning stage. Overall, the integration of robotics can elevate injection molding capabilities significantly. However, it requires commitment and a clear strategy.

Impact of Robotics on Injection Molding Efficiency

Top Brands and Models of Injection Molding Machines with Robot Features

When selecting injection molding machines with robot features, consider performance and efficiency. Many top-tier machines enhance automation, which boosts production rates. These machines can streamline workflow and minimize human error. Look for models that integrate seamlessly with robotic systems.

Tips: Always check the machine's compatibility with various robot types. A good match can greatly enhance productivity. Ensure you assess maintenance needs; some machines require regular upkeep, which can affect your operations.

The best models often come with user-friendly interfaces. Operators can quickly learn and adapt. However, not every model is perfect. Some may have limitations in flexibility. It’s essential to analyze these factors closely. An informed decision can lead to improved productivity and lower costs over time.

Future Trends in Injection Molding Technology and Robotics Integration

The landscape of injection molding technology is evolving rapidly. Robotics are becoming integral to this transformation. Recent industry reports indicate that the use of automation in injection molding could increase productivity by up to 30%. This rise stems from the demand for higher precision and reduced cycle times. Integrating robotics with injection molding machines works wonders. For instance, robots handle repetitive tasks, which minimizes human error.

However, there are challenges that need attention. The initial investment for robotic integration is high. Companies may hesitate to adopt these technologies due to the costs involved. Yet, a report by the International Journal of Advanced Manufacturing Technology shows that smart factories could save up to 25% in operational costs over five years. Robotic features enhance flexibility in production, but adapting existing processes can be tricky. Each factory has unique needs, requiring tailored solutions.

As we look ahead to 2026, the synergy between injection molding and robotics is critical. Data shows that over 50% of manufacturers are already exploring these innovations. However, not all companies are prepared for this shift. Training staff to work alongside robots poses another hurdle. Balancing human talent and technology will be key to successful integration. The future is bright, but the path is not without its bumps.

2026 Best Injection Molding Machine With Robot Features

| Machine Model | Clamping Force (tons) | Injection Speed (mm/s) | Cycle Time (seconds) | Robot Integration (Yes/No) | Special Features |

|---|---|---|---|---|---|

| Model A | 120 | 250 | 12 | Yes | Energy-efficient, Smart Controls |

| Model B | 150 | 230 | 10 | Yes | Modular Design, AI Integration |

| Model C | 100 | 270 | 14 | No | Compact Size, User Friendly |

| Model D | 200 | 220 | 11 | Yes | Multi-Stage Injection, High Precision |

| Model E | 180 | 240 | 9 | Yes | Automated Part Removal, High Reliability |