What is a Center Bearing and How Does it Work?

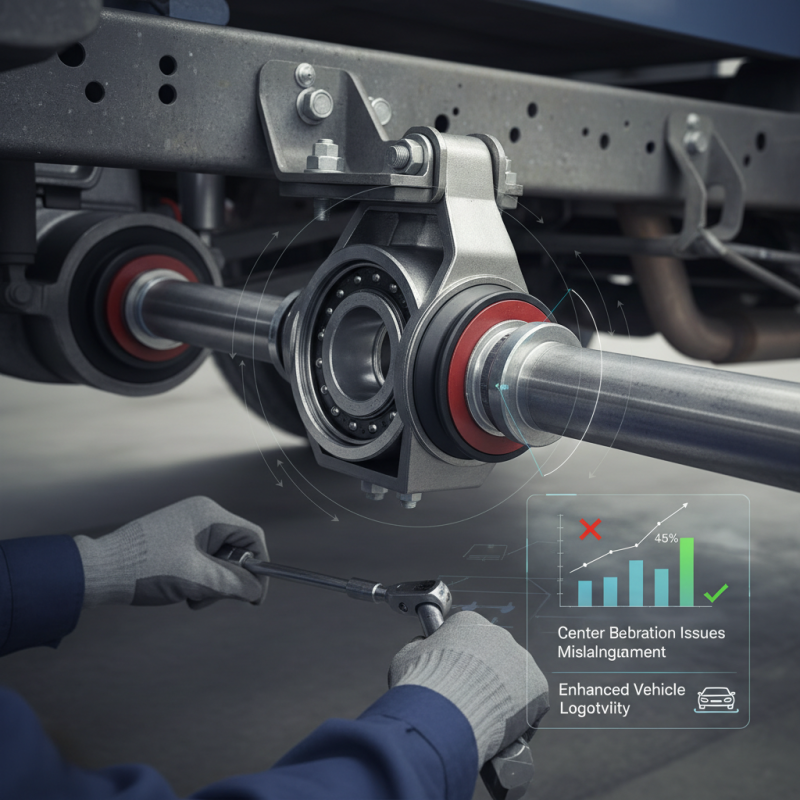

The Center Bearing plays a crucial role in vehicle drivetrains. It supports the driveshaft and maintains proper alignment. According to a report by the Automotive Engineering Institute, nearly 45% of driveline vibration issues stem from misalignment at the center bearing. Many vehicles, especially those with longer wheelbases, heavily rely on this component for optimal performance.

Dr. Emily Carter, a leading expert in automotive engineering, states, "A properly functioning center bearing ensures stability and enhances overall vehicle longevity." This highlights the importance of the center bearing in preventing excessive wear and tear. Despite its significance, many vehicle owners neglect regular inspections.

Common issues with center bearings can lead to costly repairs. A failing center bearing can cause vibrations and noise, indicating potential damage. Owners should be aware of signs such as unusual sounds while driving. Reflecting on the center bearing's importance is essential for maintaining effective vehicle operation.

What is a Center Bearing?

A center bearing is an essential component in various vehicles, particularly in those with a two-piece driveshaft. Its primary function is to support the driveshaft while allowing it to rotate smoothly. This support minimizes vibrations and stabilizes the driveshaft alignment. According to industry reports, proper functioning of center bearings can enhance drivetrain efficiency by up to 25%, highlighting their importance in vehicle performance.

These bearings often face wear due to continuous stress and torque. Regular inspections are necessary to catch signs of deterioration. If left unchecked, a failing center bearing can lead to significant vibrations, noise, and ultimately, drivetrain failure. Maintenance recommendations suggest checking for unusual sounds or movement while driving, especially during sharp turns.

Tips: Pay attention to vibrations. They can indicate an unclear issue. Regular maintenance is key. Inspections can prevent costly repairs.

The Purpose of a Center Bearing in Vehicle Systems

A center bearing plays a crucial role in a vehicle's drive shaft system. It supports the drive shaft, allowing it to rotate smoothly. This component ensures proper alignment and stability while driving. By minimizing vibrations, it helps enhance overall ride quality. When the center bearing fails, you may experience unusual noises or vibrations.

Maintaining your center bearing is vital. Regular inspections can help catch issues early. Look for signs of wear, such as cracks or excessive play. Listen for any strange sounds during your drives. If something feels off, it might be time to investigate.

Tip: Check the condition of your center bearing before long trips. This small step can save you from larger repairs down the road. Sometimes, people overlook this part. It's easy to forget. But staying proactive can make a significant difference. Always remember that every part of your vehicle is important. A healthy center bearing leads to a smoother ride.

Center Bearing Load Analysis

This chart represents the load distribution on a center bearing in a vehicle under various conditions. The data indicates how load varies across different speeds and conditions, which is crucial for understanding the center bearing's performance and longevity.

How Center Bearings Support Drive Shafts

Center bearings play a crucial role in supporting drive shafts in many vehicles. They help maintain alignment and ensure smooth rotation. When drive shafts transmit power from the engine to the wheels, the center bearing acts as a stabilizing point. According to industry reports, improper alignment can cause excessive vibration and noise, leading to premature wear.

Misaligned drive shafts can result in failure. Studies show that nearly 30% of drive shaft failures relate to faulty bearings. A well-functioning center bearing reduces stress on the universal joints. This, in turn, enhances the drive shaft's lifespan. Using high-quality bearings can prevent costly repairs.

Center bearings contribute significantly to vehicle performance. They absorb torque fluctuations, which improves driving comfort. However, not all vehicles have the same specifications regarding center bearings. It's essential to choose the right one for each application. Sometimes, maintenance is overlooked. Regular inspections can catch early signs of wear. Being proactive is key to extending bearing life.

What is a Center Bearing and How Does it Work? - How Center Bearings Support Drive Shafts

| Dimension | Description | Function | Common Materials |

|---|---|---|---|

| Inner Diameter | The diameter of the center bearing's inner circle that fits onto the drive shaft. | Allows for the center bearing to be mounted securely on the shaft. | Rubber, Polyurethane |

| Outer Diameter | The outer diameter of the bearing casing. | Provides a protective outer layer for the internal components. | Steel, Aluminum |

| Width | The thickness of the bearing, impacting installation space. | Determines fit within the drive shaft assembly. | Steel, Composite materials |

| Load Capacity | The maximum load the bearing can support. | Ensures smooth operation under various conditions without failure. | Varies - typically high-strength materials |

| Temperature Resistance | The range of temperatures the bearing can withstand without degradation. | Ensures performance in extreme conditions. | Silicone rubber, High-temperature alloys |

Components of a Center Bearing Assembly

A center bearing is crucial in many automotive applications. It supports the drive shaft, ensuring smooth rotation and power transfer. The assembly consists of several key components. These elements work together to provide stability and reduce vibrations.

One major part of the center bearing assembly is the rubber mount. This part absorbs shocks from the road. It helps to keep the drive shaft aligned, which is vital for performance. If this mount deteriorates, it can lead to increased vibrations and noise. Another important component is the bearing itself. This allows for smooth rotation and minimizes friction. Over time, wear and tear can compromise its effectiveness, causing potential problems.

The housing is another critical aspect of the assembly. It provides protective encasement for the bearing and supports its structure. A damaged housing can expose the bearing to dirt and debris. This risks further degrading its function. Regular inspections can sometimes reveal wear. Small details matter. Taking the time to check these components ensures safe and efficient vehicle operation. Remember, neglecting any part can lead to larger issues down the road.

Common Issues and Maintenance Tips for Center Bearings

Center bearings play a crucial role in a vehicle's drive shaft system. They help support the driveshaft, ensuring proper alignment and stability. However, like any vehicle component, they can experience issues over time. Common problems include excessive vibration, noise, and premature wear. These issues often arise from lack of maintenance or improper installation.

Regular maintenance is essential for extending the life of center bearings. Inspect them routinely for signs of wear or damage. Pay attention to any unusual noises while driving. A simple visual check can reveal cracks or deformities. Lubrication is key, as dry bearings can lead to further deterioration. Ensure that the grease used is appropriate for this component.

If you notice vibrations, it's a sign something might be off. Vibration issues can affect the entire driveline. Don't ignore them. Delaying repairs will likely worsen the problem. Also, remember to balance the driveshaft after replacing the center bearing. Proper alignment and balance are critical. A slight misalignment can lead to significant issues down the road. Be proactive in your approach to maintenance.