How to Choose the Best Dust Collector for Your Needs?

Choosing the right dust collector can significantly impact your workspace. A suitable dust collector helps maintain a clean and safe environment. It is essential to understand your specific needs before making a purchase.

Different dust collectors are available on the market. Some are portable, while others are designed for fixed setups. The size of your workspace and the type of materials being processed will determine which option is best. Don’t overlook airflow capacity or the type of filtration system. A weak filter can lead to dust escaping back into the air, which defeats the purpose of having a dust collector in the first place.

Selecting a dust collector is not just about the price. You must consider the long-term performance and maintenance as well. Reflect on how often you’ll need to clean or replace filters. Investing in the right dust collector pays off in the long run. It’s about creating a healthier work environment.

Understanding the Importance of Dust Collectors in Various Industries

Dust collectors play a crucial role in various industries by maintaining air quality and ensuring health safety. According to a report by the Environmental Protection Agency, 1.5 million people in the U.S. face respiratory issues due to poor air quality in industrial settings. This statistic highlights the urgency of effective dust management. Factories, woodworking shops, and metalworking plants are among the most affected. They generate significant dust and pollutants that can harm workers and the environment.

Implementing a dust collection system can reduce these risks significantly. A study from the National Institute for Occupational Safety and Health pointed out that facilities with proper dust collection systems can decrease airborne particles by up to 90%. However, many businesses overlook this need. Some may opt for cheaper, less effective solutions, thinking they save costs. These decisions can lead to higher long-term expenses due to health-related issues among workers.

Choosing the best dust collector requires careful evaluation. Understanding the specific types of dust generated is vital. For instance, wood dust behaves differently than metal shavings. A miscalculation here can compromise safety or lead to inefficient operations. It's essential to regularly assess the dust collector's performance. An underperforming system can create dangerous environments and lead to regulatory penalties. Reflecting on these elements is key to making informed choices in dust collection.

Key Factors to Consider When Selecting a Dust Collector

Choosing a dust collector requires careful consideration of several key factors. First, evaluate your workspace size. A smaller area may benefit from a portable unit, while larger spaces need more robust systems. Consider the types of materials you use as well. Different dust collectors handle diverse particles effectively. For instance, wood dust and metal shavings require different filtration systems. Ensure the collector’s specifications match your needs.

Another aspect is the airflow requirement. Measure the needed cubic feet per minute (CFM) to maintain a clean environment. You might think that bigger is always better. However, oversized units can waste energy and create unnecessary noise. Often, a smaller, efficient model can achieve better results. Additionally, maintenance is vital. Some systems need frequent filter changes or cleaning. This can be a hassle and increase operational costs if you're not careful.

Finally, budget constraints play a significant role. A low-cost model may save money upfront but could lead to higher expenses later on. Investing in the right equipment upfront can save time and money over time. Reflect on these factors. Taking time to research might seem tedious but is essential for effective dust management.

Types of Dust Collectors and Their Applications

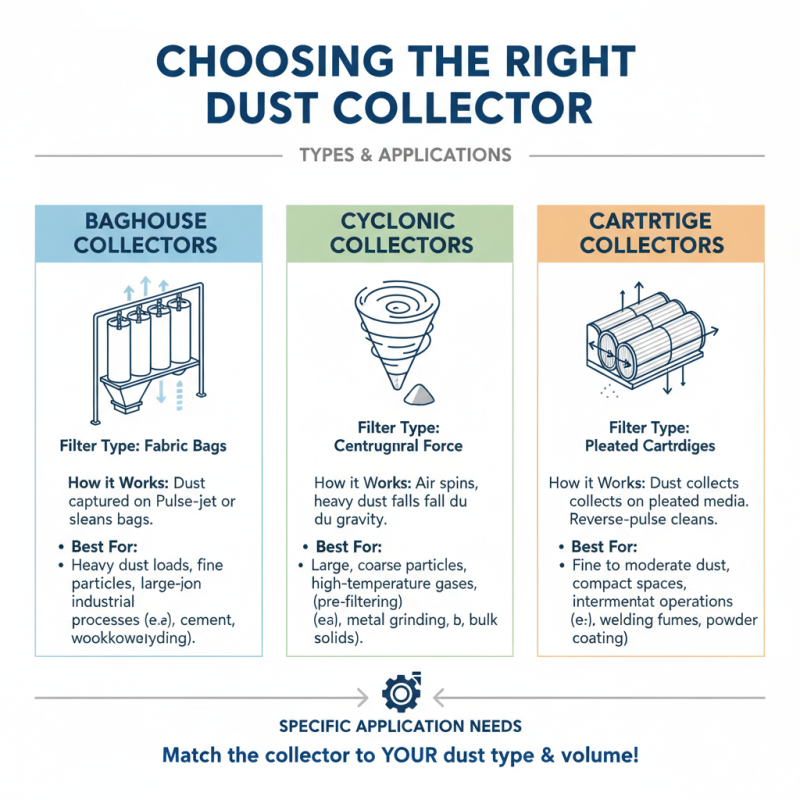

Choosing the right dust collector involves understanding its types and specific applications. There are several types of dust collectors available, including baghouse, cyclonic, and cartridge collectors. Each type functions differently and suits various environments.

Baghouse collectors are excellent for large-scale operations. They capture fine particles effectively. However, they require regular maintenance. Cyclonic collectors are often used for lighter dust. They work well in woodworking shops but can struggle with finer particulates. Cartridge collectors are compact and efficient. They are ideal for smaller spaces but may come with higher initial costs.

Tips: Consider your workspace size and type of dust generated. Ensure easy access for maintenance. Assess your budget but prioritize quality. Remember, a mismatched collector may lead to inefficiency. It can result in ongoing issues you’ll need to address later. Selecting the wrong type could mean increased dust and health risks. Take your time to evaluate each option carefully.

Evaluating Your Space and Airflow Requirements

When selecting a dust collector, understanding your space and airflow requirements is crucial. Industry studies indicate that workspace size directly influences dust collector performance. For instance, a shop with limited floor space may need a compact design that still delivers strong suction. Airflow, measured in cubic feet per minute (CFM), is vital. A larger space often requires a unit with a higher CFM to maintain air quality, especially if woodworking or metalworking operations generate substantial dust.

Evaluating airflow requirements also involves considering the number of tools in use. Some experts recommend a minimum of 100 CFM per tool for optimal performance. However, many users overlook the airflow needed when multiple tools are running simultaneously. This common oversight can lead to poor dust control and increased health risks. It’s essential to account for peak usage to determine the right capacity.

Another factor is the type of dust produced. Different materials create varying particle sizes and weights, affecting collection efficiency. For heavier wood particles, a more powerful system might be necessary. Industry data suggests that 30% of workplaces underestimate their dust collection needs due to a lack of precise measurements and airflow assessments. This gap can result in inadequate systems causing operational frustrations and health hazards.

How to Choose the Best Dust Collector for Your Needs

Maintenance and Operational Costs of Dust Collectors

When selecting a dust collector, maintenance and operational costs are vital aspects to consider. Regular maintenance helps keep your system efficient. Neglecting it can lead to higher energy costs and reduced performance. A clean filter works better. Clogged filters increase energy consumption. Remember, clean equipment is always cost-effective.

Tip: Consider a dust collector with easy access for maintenance. It saves time and reduces frustration. Also, check the availability of replacement parts. This can affect long-term costs. Look into the maintenance schedule, which should be manageable for your operations.

Operational costs can vary based on your choice. Factors include energy consumption, filter replacements, and repairs. Calculate these costs before purchasing. Some models may be cheaper upfront but expensive in the long run. Reflect on the total cost of ownership. Always tailor your choice to the unique needs of your workspace.

Related Posts

-

7 Reasons Why the Best Sawdust Collector is Essential for Your Workshop

-

What is the Efficiency of the Best Baghouse Dust Collector in Industrial Applications

-

How to Choose the Right Dust Collector for Your Industrial Needs Based on Air Quality Standards

-

5 Compelling Reasons Why the Best Magnetic Drum Separator is Essential for Your Business

-

The Future of Efficient Dust Control with Advanced Bag House Systems

-

Exploring Innovative Alternatives to Sand Dryers for Efficient Industrial Solutions