How to Choose the Best Hydraulic Hose for Sale?

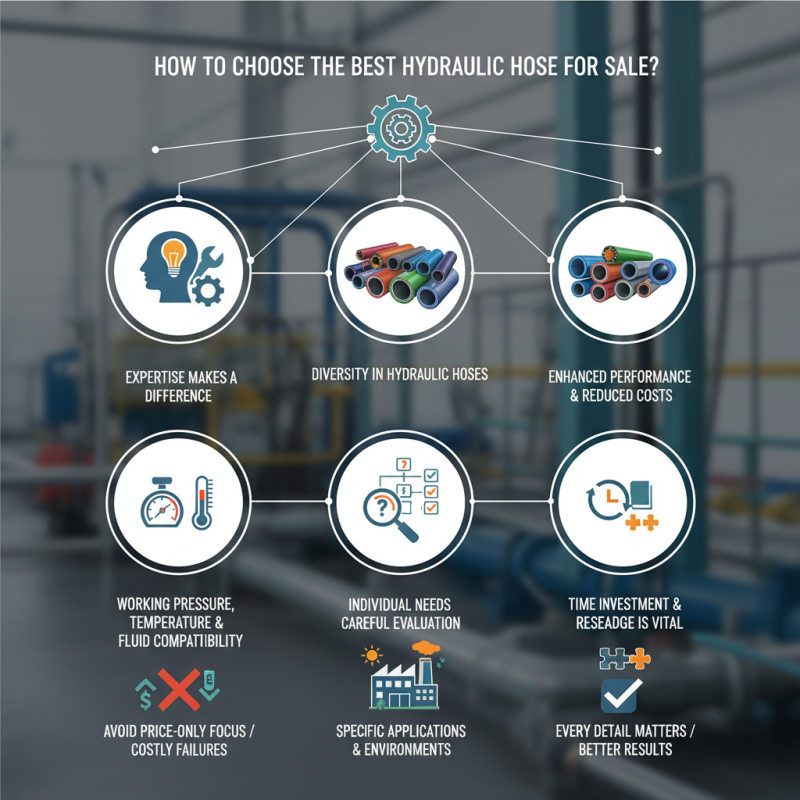

When selecting the best hydraulic hose for sale, expertise can make all the difference. John Smith, a leading expert in hydraulic systems, once remarked, "Choosing the right hydraulic hose is crucial for system efficiency and safety." Understanding the diversity in hydraulic hoses is essential. The right choice can enhance performance and reduce maintenance costs.

Yet, not all hoses are created equal. Factors such as working pressure, temperature range, and compatibility with fluids must be considered. In this complex landscape, it’s easy to make mistakes. Many buyers focus solely on price, ignoring crucial specifications. This can lead to costly failures down the line. Observing the market reveals numerous options, yet the best fit relies on individual needs.

The process requires careful evaluation. Users must consider their specific applications and environments. There’s no universal solution. One must reflect on how different hoses behave under varying conditions. Ultimately, investing time in researching hydraulic hoses for sale will yield better results. Knowledge is vital, and every detail matters.

Understanding Hydraulic Hose Specifications and Standards

Hydraulic hoses are crucial for various industries. Choosing the right one requires understanding specifications and standards. A hose’s diameter affects flow rate. It dictates how much fluid can move through. A too-small diameter may restrict flow, leading to system failures. Pressure ratings are equally important. High-pressure applications need hoses designed to withstand more force. Look for specifications that meet or exceed your system's requirements.

Materials used in hose construction also impact performance. Consider the environment where the hose will be used. Will it be exposed to extreme temperatures or corrosive substances? The choice of rubber or synthetic materials can make a difference. Careful examination of temperature and chemical resistance is required. Inadequate choices can lead to premature wear or failure.

It's essential to adhere to industry standards. These standards ensure safety and reliability. However, not all hoses on the market comply. Sometimes, manufacturers cut corners. Verify whether hoses meet accepted guidelines. Check for certifications that validate quality. Investing time in research can prevent costly mistakes down the line.

Evaluating Pressure Ratings for Different Hydraulic Applications

Choosing the right hydraulic hose involves understanding pressure ratings. Different applications demand various pressure levels. Low-pressure systems typically operate below 150 PSI. These hoses are durable but not suited for high-stress jobs. For medium-pressure tasks, hoses can handle from 150 to 3000 PSI. Understanding your application is crucial here.

High-pressure hoses exceed 3000 PSI. These are vital for heavy machinery and hydraulic presses. However, they require careful selection. Overextending a hose’s pressure rating can lead to catastrophic failures. Assessing the working environment is important. Temperature fluctuations, bends, and exposure affect hose integrity.

Proper fitting and maintenance are often overlooked. They play a role in safety and performance. Regular inspections can prevent leaks and bursts. Users sometimes ignore these checks. They assume everything will work as intended. This mindset can have dangerous consequences. Knowing your pressure requirements helps, but it’s not the only factor.

Material Composition: Choosing the Right Hose for Your Environment

When selecting a hydraulic hose, material composition plays a significant role. Different environments demand different materials. For instance, rubber hoses are flexible and resilient. They perform well in moderate temperatures. However, in extreme heat or cold, rubber may degrade quicker.

Consider the chemical exposure, too. If the hose will contact oils or solvents, synthetic materials are preferable. They can withstand harsher conditions. But remember, the choice isn’t always clear-cut. Sometimes, synthetic hoses may seem costly upfront, yet they last longer, reducing replacement frequency.

Water-based environments require careful selection. A hose that’s too rigid may crack under pressure. Conversely, too much flexibility can lead to kinking. Finding the right balance is essential. Testing in your specific setting may reveal issues that theory doesn’t foresee. Be prepared to adapt your choices based on real-world performance. This requires ongoing assessment and willingness to change.

Analyzing Hose Diameter and Length for Optimal Performance

When selecting a hydraulic hose, hose diameter and length are crucial. The diameter affects fluid flow rate and pressure. A smaller diameter may lead to increased resistance, reducing efficiency. Research shows a 25% increase in flow capacity with an increase in diameter from 3/8 to ½ inch. This is significant in applications requiring high efficiency.

Length also plays a pivotal role. Longer hoses can lead to pressure drops. Data indicates that every additional foot of hose can reduce pressure by 0.5 to 3 psi, depending on the diameter and fluid type. Too long of a hose may result in difficulty managing hydraulic fluid movement. However, an overly short hose can cause premature wear and tear, creating a balancing act that must be carefully considered.

Choosing the correct specifications is a challenge. The industry's margin for error is thin. Making the wrong choice can affect the entire hydraulic system. This issue can lead to breakdowns and costly repairs. Reflecting on hose length and diameter is valuable for performance and longevity, yet many overlook these details. Proper consideration is essential for ideal performance.

Identifying Common Hydraulic Hose Failures and Maintenance Practices

Hydraulic hoses play a crucial role in many machinery operations. However, they are prone to failures. Common issues include leaks, cracks, and bulges. These problems arise from excessive pressure, wear, or exposure to extreme temperatures. Regular inspections can help identify these early signs.

Maintenance practices are key to enhancing hose longevity. Keep hoses clean and debris-free. Using proper fittings and connectors is also important. Pay attention to the installation angle. An improper angle can lead to stress and eventual failure. Not all hoses are created equal; using the wrong type could lead to inefficiencies.

Failure to replace worn-out hoses on time can lead to costly downtime. An overlooked crack might result in a burst hose. Therefore, regular monitoring and proactive maintenance are essential. Understanding these issues can empower operators to make better choices. Consider regular training for the team to recognize these issues early.