What is a Metallurgical Bridge Crane and How Does It Work?

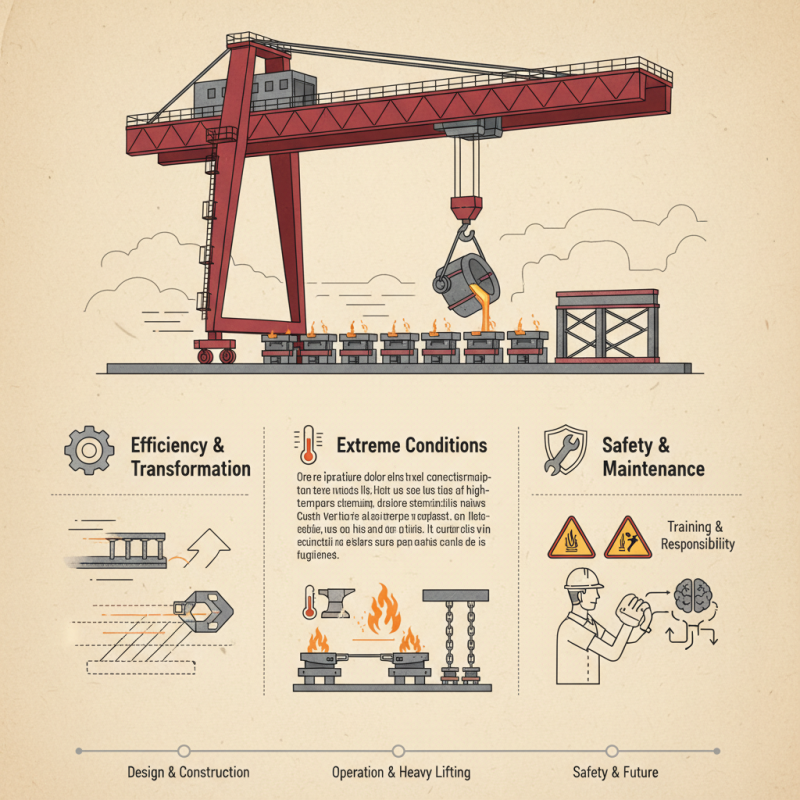

In the industrial sector, the Metallurgical Bridge Crane plays a crucial role. Expert Mark Thompson, a leading figure in crane technology, states, “The efficiency of a Metallurgical Bridge Crane can transform a manufacturing process.” This statement highlights its impact on operations.

Understanding how a Metallurgical Bridge Crane functions is essential. These cranes are designed for heavy lifting in metal production. They typically operate in environments with high temperatures and heavy loads. The design must withstand extreme conditions, reinforcing the need for robust construction.

Yet, there are challenges. Maintenance and safety standards are critical. Operators must be trained thoroughly. Mismanagement can lead to accidents, which emphasizes the importance of ongoing training. The Metallurgical Bridge Crane is powerful, but it requires responsibility and awareness for safe operations.

What Defines a Metallurgical Bridge Crane in Industrial Settings?

Metallurgical bridge cranes are essential in industrial sectors, particularly in metal processing and heavy manufacturing. These cranes are designed to handle molten metal, heavy components, and bulky loads efficiently. They typically employ a robust design to ensure maximum safety and reliability. According to industry reports, approximately 30% of workplace accidents in foundries are linked to improper crane operation. This highlights the need for stringent safety standards and operator training.

In industrial settings, a metallurgical bridge crane can lift loads surpassing 100 tons. This capability is crucial for tasks involving raw materials like steel or aluminum. The operational speed of these cranes can vary between 10 to 50 feet per minute, depending on the load and application. However, not all facilities utilize advanced safety features, resulting in potential hazards. Regular maintenance protocols are often overlooked, leading to increased downtime and operational inefficiency.

Operators require specialized training to navigate the complexities of metallurgical bridge cranes. Many facilities face challenges with outdated equipment, causing them to fall short of productivity goals. Real-time data reporting systems can enhance performance but remain underutilized. In conclusion, the metallurgical bridge crane's design and operation are vital for industrial efficiency and safety.

Key Components and Mechanisms of Metallurgical Bridge Cranes

Metallurgical bridge cranes play a vital role in industrial settings, especially in metal processing and heavy manufacturing. These cranes consist of several key components that ensure efficiency and safety. The main structure includes the bridge, which spans the workspace, allowing the crane to move horizontally. The hoist, attached to the bridge, is responsible for lifting heavy loads.

Electromechanical systems, like motors and gears, drive these cranes. They must be robust to handle the considerable weight of materials like molten metal. Load sensors are also crucial, providing real-time feedback, which prevents overloading. It's interesting to note that the design often varies based on industry needs, reflecting the diversity of metallurgical applications.

Tip: Regular maintenance is essential. Inspect cables and pulleys regularly to prevent accidents.

Safety features are another critical aspect. Emergency stop buttons, motion sensors, and alarms are common. They help protect workers and equipment. However, flaws can occur. Sometimes, sensors fail, leading to potential hazards. Training operators thoroughly can mitigate this risk.

Tip: Implement routine safety drills. Familiarity with emergency procedures enhances team readiness.

Operational Principles: How Metallurgical Bridge Cranes Function

Metallurgical bridge cranes are vital in heavy industries. Their design allows them to operate in challenging environments like steel mills and foundries. These cranes work by moving through a series of rails. They lift and transport molten metal and heavy materials with ease. The careful coordination of their components enables precise movements.

Typically, they have a strong structure. The bridge is supported by two or more end trucks. These end trucks ride on tracks, which offer stability. An overhead hoist provides the lifting mechanism. Operators control the hoist using a pendant or remote system. This method enhances safety while maneuvering heavy loads.

However, operating metallurgical bridge cranes is not without challenges. Operators need to be aware of the heavy loads they handle. Proper training is critical to ensure safety. Regular maintenance is needed to avoid malfunctions. Any oversight can lead to severe accidents. Understanding these operational principles is essential for effective crane management.

Metallurgical Bridge Crane Data Table

| Dimension | Specification |

|---|---|

| Load Capacity | 10 - 100 tons |

| Span Length | 10 - 60 meters |

| Lift Height | 3 - 30 meters |

| Operating Speed | 0.5 - 10 m/min |

| Power Supply | 380V, 50Hz, 3 Phases |

| Control System | Manual and Remote |

| Material Handling Type | Hot Metal, Scrap, and Billets |

| Safety Features | Overload Protection, Emergency Stop |

Safety Standards and Regulations for Metallurgical Bridge Cranes

Safety standards and regulations play a crucial role in the operation of metallurgical bridge cranes. These cranes often handle heavy loads, making safety a top priority. Operators must follow specific guidelines to reduce the risk of accidents. Regular inspections are vital to ensure that all components function correctly. This includes checking wires, hooks, and brakes, among other parts. Comprehensive training for operators is also essential.

Compliance with national and local safety codes is necessary. These regulations can vary significantly based on the location and industry. Operators and managers should familiarize themselves with these guidelines. Inadequate attention to safety can lead to tragic incidents. Organizations often struggle with adherence to these regulations due to insufficient training or lack of resources. Creating a culture of safety within the workplace takes effort but is worth it.

Additionally, proper maintenance practices are indispensable. Neglecting maintenance can result in failures or dangerous situations. Timely repairs can extend the lifespan of the equipment. Engineers should also consider upgrading outdated systems. By doing so, they can improve safety and efficiency. Striking the right balance between maintenance, regulation, and employee training is challenging, yet essential for success.

Applications and Benefits of Metallurgical Bridge Cranes in Industries

Metallurgical bridge cranes are crucial in heavy industries like steel production. They are designed to handle molten metal, heavy equipment, and bulky materials. This type of crane offers seamless operation in environments with high temperatures. They can lift impressive weights, ensuring safety and efficiency.

These cranes are essential in foundries and ironworks. They facilitate the movement of materials and products. Each crane is built with robust materials to withstand harsh conditions. Many industries benefit from their ability to operate in confined spaces. However, they require careful maintenance and trained operators. Improper handling can lead to accidents.

One significant advantage is their flexibility in design. They can be customized for various tasks. However, such customization may also increase costs. Each facility must weigh the benefits against potential expenses. Efficiency can be achieved, but not without challenges. It requires thoughtful implementation and constant evaluation.

Metallurgical Bridge Crane Applications and Benefits

This chart illustrates the various applications of metallurgical bridge cranes in different industries. The most prominent application is in steel production, followed by metal recycling and foundries, showcasing the crucial role these cranes play in heavy industries.