Unlocking Performance with the Technical Parameters of Best Axial Fans for Global Buyers

In the rapidly evolving industrial landscape, axial fans have become essential components across various applications, ranging from HVAC systems to electronics cooling. According to a recent report by MarketsandMarkets, the global axial fan market is projected to reach $XX billion by 2025, driven by the increasing demand for energy-efficient cooling solutions in industrial processes. The technical parameters of these fans, such as blade design, motor efficiency, and airflow performance, are pivotal in unlocking their full potential. Understanding how to select the best axial fans for specific industry applications can greatly impact operational efficiency and energy consumption. This blog will explore real-world case studies from different sectors, offering insights into optimal axial fan performance while providing practical guidelines on how to choose the right fan for your needs.

Understanding Axial Fan Basics: Key Components and Functionality

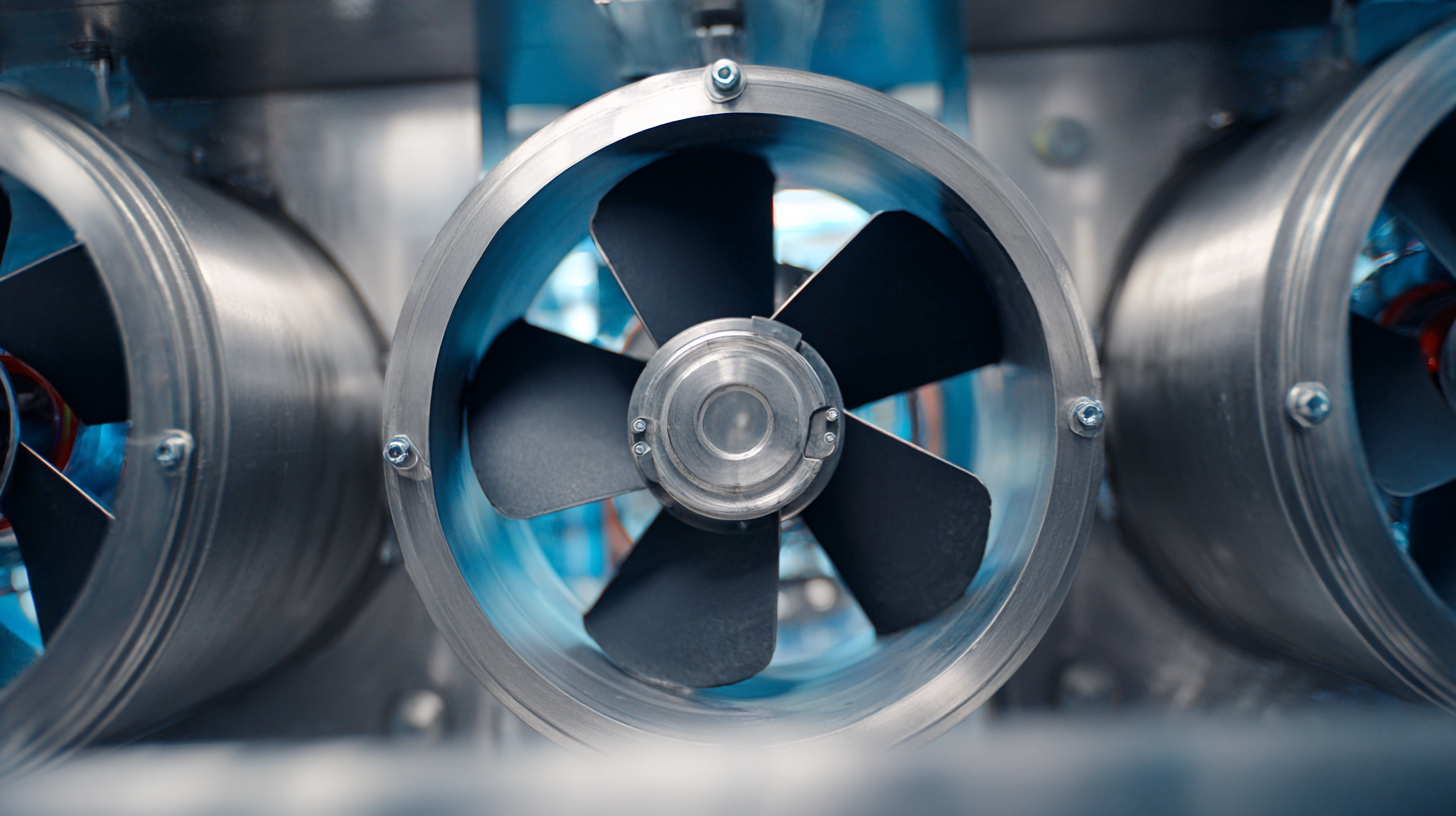

Understanding the basics of axial fans is essential for global buyers looking to enhance their operational efficiency. Axial fans are engineered to move air parallel to the fan's axis, making them ideal for applications where high airflow and low pressure are required. Key components such as blades, motors, and housing significantly influence the fan's performance. According to industry reports, axial fans account for approximately 40% of the global ventilation market, highlighting their vital role in various sectors, including HVAC, industrial processes, and cooling systems.

When selecting an axial fan, it's crucial to consider factors such as airflow rate, pressure drop, and efficiency ratings. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that upgrading to high-efficiency axial fans can improve energy consumption by up to 30%. Buyers should also ensure that the fan's specifications align with their specific application requirements, which can vary widely depending on the operational environment.

**Tips:** Always check the fan's sound levels, especially in residential or quiet working areas, as noise can significantly impact comfort. Additionally, opting for corrosion-resistant materials can enhance the fan's lifespan, particularly in humid or outdoor environments. Lastly, integrating variable speed drives can provide further energy savings by allowing for optimized airflow adjustments.

Performance of Axial Fans: Key Technical Parameters

Evaluating Performance Metrics: CFM, RPM, and Noise Levels Explained

When selecting axial fans, understanding key performance metrics is crucial for global buyers aiming for optimal airflow and efficiency. The three primary parameters to consider are Cubic Feet per Minute (CFM), Revolutions Per Minute (RPM), and noise levels. CFM measures the volume of air the fan can move in a minute, directly influencing cooling efficacy in various environments. Higher CFM values indicate more substantial airflow, which is essential for larger spaces or industrial applications where effective ventilation is paramount.

RPM, on the other hand, reflects the fan's speed and directly correlates with airflow potential. However, a balance must be struck, as excessively high RPM may lead to increased noise levels. Noise is a critical factor for many users, particularly in residential settings where silence is valued. Therefore, when evaluating axial fans, it's important to consider a model that not only meets desired airflow metrics but also maintains a tolerable noise level for the intended application. By analyzing these performance metrics, buyers can make informed decisions that suit their specific cooling needs.

Unlocking Performance with the Technical Parameters of Best Axial Fans for Global Buyers

| Model | CFM (Cubic Feet per Minute) | RPM (Revolutions Per Minute) | Noise Level (dB) | Efficiency (%) |

|---|---|---|---|---|

| Axial Fan A | 800 | 1200 | 45 | 85 |

| Axial Fan B | 950 | 1400 | 50 | 88 |

| Axial Fan C | 1100 | 1600 | 55 | 90 |

| Axial Fan D | 1200 | 1800 | 52 | 92 |

| Axial Fan E | 1050 | 1500 | 48 | 87 |

How to Select the Right Axial Fan for Your Specific Application Needs

When selecting the right axial fan for your specific application needs, it is crucial to consider various technical parameters that significantly impact performance. One of the primary factors is airflow capacity, measured in cubic feet per minute (CFM). Depending on your application—be it cooling electronic equipment, ventilating a warehouse, or exhausting fumes—the required CFM will vary. High-performance axial fans can move large volumes of air at lower pressures, making them ideal for applications that demand efficiency over resistance.

Another vital aspect to evaluate is the fan's size and blade design. Larger fans with well-angled blades can improve airflow while reducing energy consumption. Additionally, the material of the blades is important; for instance, aluminum blades may provide better durability against corrosion in harsh environments. Noise levels, measured in decibels (dB), should also be taken into account, especially in sensitive settings like hospitals or laboratories. Selecting a fan that balances these technical parameters will help you achieve optimal performance tailored to your unique requirements.

Technical Specifications that Impact Efficiency and Longevity

In the pursuit of enhanced efficiency and longevity, understanding the technical specifications of axial fans is crucial for global buyers. These fans operate on specific parameters that significantly influence their performance, including airflow rate, static pressure, and power consumption. Buyers should pay attention to these details, as they directly impact the energy efficiency of the fan and its operational longevity. Selecting axial fans with optimized specifications can lead to improved performance in various applications, from cooling systems to industrial machinery.

Recent advancements in technology reflect a similar trend in other sectors, such as the development of electric vehicle batteries and household appliances. For instance, integrating machine learning in battery management ensures extended lifespans through precise estimations of remaining useful life (RUL). This focus on performance metrics resonates across industries, highlighting the importance of selecting products designed with longevity in mind. Whether it's choosing the best axial fans or the latest energy-efficient appliances, buyers benefit from prioritizing technical specifications that enhance durability and operational efficiency.

Navigating Global Standards and Certifications for Axial Fans

When considering the global market for axial fans, understanding the various standards and certifications is crucial for buyers looking to optimize performance. These certifications often serve as a benchmark for quality, safety, and efficiency within different industries such as oil and gas, power generation, and industrial manufacturing. Compliance with global standards not only facilitates international trade but also assures buyers of the product’s reliability and suitability for specific applications.

Navigating through the myriad of certifications can be challenging, yet it is essential. Each region may have its own set of regulations that influence design, manufacturing processes, and operational benchmarks. For global buyers, staying abreast of these evolving standards ensures that the axial fans they invest in will meet local requirements while delivering top-tier performance. This alignment not only enhances the operational efficiency of their systems but also mitigates potential risks associated with non-compliance. Ultimately, a well-informed procurement process, focused on technical parameters alongside global certifications, positions buyers to make the most strategic choices in axial fan selection.